Introduction

In 1962, the five Skuldelev Ships were found and excavated from the sea bed in Roskilde Fjord. They dated from the 11th century, when the ships were scuttled to form a blocade in the water inlet.

A museum building was erected for exhibiting the ships after conservation, within a large open hall. The ships have been conserved with PEG (polyethylene glycol). The museum building is a concrete building located just inside the water line of the inlet (fig. 1).

Approximately 150,000 people visit the museum each year.

| Fig. 1: | The museum building, winter 2003. The water of Roskilde Fjord stops right in front of the facade windows. At the time of the photograph the inlet was frozen. |

The problem with dust

As the ships are exhibited in the open gallery without any barrier to the visitors (fig. 2), the ships become very dirty. They are therefore cleaned once a year by a conservator, mainly by vacuum cleaning. This is a major and time-consuming job, not without risk of mechanical damage to ships. Small components may be sucked up, and at some spots the dust can be hard to remove.

In addition, we had concerns that the dust contained chemically aggressive compounds, which would deteriorate the wood surfaces - eg. sodium chloride from the water inlet.

We carried out an investigation of the dust deposited on the ships: to establish the contents, and the sources. The level of soiling was also established. Only coarse particles were investigated (>2 µm diameter). Sampling was limited to the ships Skuldelev 1 and Skuldelev 3.

|

Fig. 2: | The wreck of Skuldelev 3. This ship was a small coastal trader.

Visitors are able to walk on the path all way around the ship, and to view into the ship from a small platform at the back. The distances from the path to the rails of the ship are between 1.35-1.65m. |

Methods

Dust layers were sampled on gelatine dust lifters [1]. Sampling directly on objects' surfaces should be carried out with great care, as the dust lifter may also lift fragile parts off the object. By this method the "old" dust layer can be investigated.

By placing a clean tile or glass slide horizontally on or near the object for a period of time, it is possible to collect only the "new" dust which falls on the surface during the exposure time. The soiling level of the location can then be defined as the number of particles per area unit, and/or the area fraction covered by the new dust, taking the exposure time into account. Sampling of new dust was performed in cross section profiles across the ships (near visitor areas, on sides of ship, in the middle of ship. (See also fig. 4).

The gel foil samples were visually analysed for their contents by light microscopy. The particle count, area fraction coverage, and particle size distribution, were analysed from digital images of 40X magnification of the samples, by ImageJ software [2].

The inorganic contents of the dust was analysed by Scanning Electron Microscopy (LV-SEM) element mapping. This was done both on new dust, which was sampled directly on SEM stubs placed horizontal on the ships, and on old dust collected from the wood surface.

The organic contents were analysed by GC/MS, soxhlet extracted in methylene chloride from dust collected by vacuum cleaning.

Results

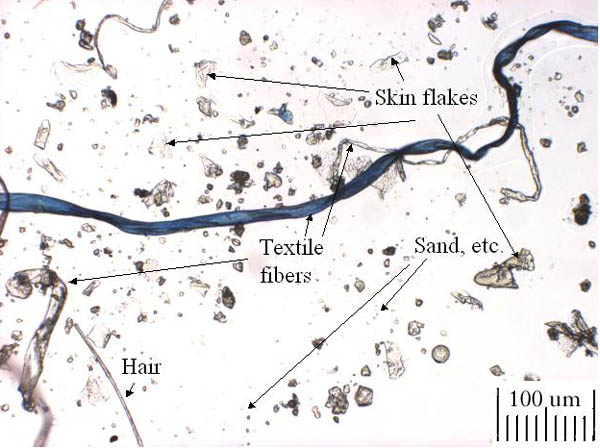

At the time of sampling "old" dust layers, seven months had passed since the last vacuum cleaning of the ships. The typical soiling density on horizontal surfaces was then approx. 17% coverage. By visual microscopy, textile fibres, skin flakes, human hair, and sand were readily identified. Textile fibres were many, and within those many blue (blue denim?) fibres.

Fig. 3: Dust layer from horizontal surface of Skuldelev 1.

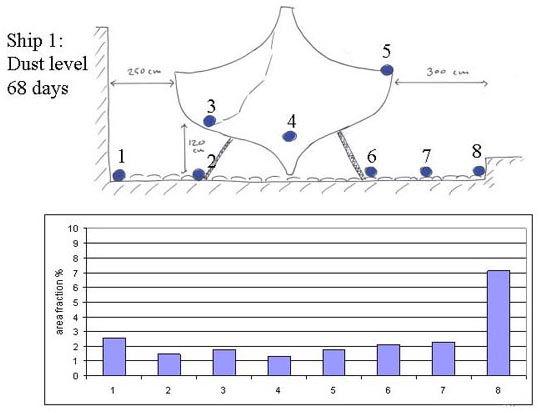

After 68 days of exposure, new dust covered up to 7% surface area on the ground just next to the visitor path at ship 1. About 1.5 m from the visitor path this was reduced down to 2-3%, and again down to less than 1.5% in the middle of Skuldelev 1 (fig. 4). A similar pattern was found for Skuldelev 3.

|

Fig. 4: | Sampling spots across Skuldelev 1. The diagram shows the area fraction covered by new dust after 68 days at each spot. |

Looking into the "soiling rate", the dust level at sampling spot no. 3 (Skuldelev 1) was determined after 22 days, 68 days, and approx. 7 months. From this a non-committal prediction on the yearly dust covering rate was made, predicting 25-30% (table 1).

| Table 1: Dust level, 1 mm2 horizontal surface, Skuldelev 1, spot 3 |

| 22 days | 41 particles | 0.2% coverage |

| 68 days | 270 particles | 1.8% coverage |

| 7 months | >6000 particles | 16.2% coverage |

| 1 year (predicted) | | 25-30% coverage |

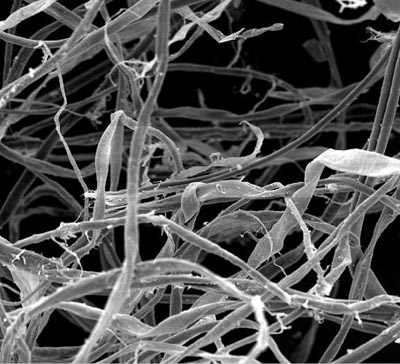

From SEM element mapping, after 22 days of dust deposition, silicates, calcium carbonate, gypsum and sodium chloride were identified. Mapping old dust collected from a horizontal surface, especially calcium carbonate and silicates was found, deposited on textile fibres (fig. 5). Sodium chloride was only found in lesser amounts.

Fig. 5: Scanning Electron Microscopy image of textile fibres in dust ball.

The small particles on the fibres consist of silicates and calcium carbonate.

The organic analysis of dust ball from vacuum cleaning, showed fatty acids, carboxylic acids, alkanes, pthalates, and to our surprise traces of TXIB (2,2,4-trimethyl-1,3-pentanediol diisobutyrate), a low viscosity plasticizer which helps to produce a non-tacky surface on PVC floorings etc. (fig. 6).

Fig. 6: Chromatogram of extraction from dust.

Peaks for carboxylic acids, phtalates, alkanes and TXIB are marked.

Discussion

The dust on the ships consists primarily of textile fibres, skin flakes and silicates, and only to a lesser degree sodium chloride.

Both visual microscopy, organic and inorganic analyses suggest, that the particles and the compounds found in the particles mainly originate from indoor human activities, whether it is release of textile fibres, skin and hair particles from people moving around, or it is calcium carbonate and silicates from the buildings concrete surfaces.

The find of TXIB is surprising. This plastisizer normally originates from PVC floor tiles etc., of which there in none in the exhibition hall. However, such floorings may have been found elsewhere in the museum previously, this has to be investigated.

Sodium chloride is indeed present within the dust, but not in alarming amounts. NaCl is problematic if deposited on moist sensitive surfaces, as it will create a surface micro-climate of a high relative humidity. However, this seems not to be a problem here.

Based on the image analysis of the dust deposition layers, we may expect up to 30% area coverage in one year, on horizontal surfaces. The short sampling periods (22 - 68 days) underestimate this, however, those were carried out during the first months (winter) of 2003. The museum receives over half of its annual visitors during only three summer months, which probably increases the dust load considerably.

While the dust is not a direct deterioraton agent with regard to the conserved wood, it is indirectly jeopardizing the condition of the ships, as mechanical damage may arise from cleaning. Cleaning is primarily carried out from an aestetic point of view. However, stopping the annual cleaning routine is not an option.

The soiling level measurements as shown in fig. 4, indicate how the dust deposition decreases when the distance between visitors and objects is increased (at least for coarse particles). This correspond well to previous studies by Yoon and Brimblecombe [3]. However, in the case of the Viking Ships Museum distances from visitor path to ships are not sufficient (being as short as 1.35m some places) to provide a satisfactory decrease of the level of soiling. This is illustrated by the area covered by dust on ships edges, which despite the distance to the visitors still recieves about 17% surface coverage over 7 months.

It is probably not possible to completely eliminate dust in such an open environment, however, placing a barrier such as glass walls with a height of 1.5 - 2 m will dramatically decrease deposition of coarse dust on the side away from visitors. From everyday use of display cases it is common knowledge, that dust can be almost completely eliminated, especially if it is possible to provide a slight overpressure in the case. While it will require a major (and costly) reorganization of the exhibition to case the ships completely, it may be worth considering if the exhibition design at some point are to be renewed anyway.

Another solution is simply to continue to vacuum clean the ships once a year, being aware of the potential consequences.

Acknowledgements

Anette Hjelm Petersen - waterlogged wood conservator

Jens Glastrup - GC/MS

Ulrich Schnell - SEM

(all National Museum of Denmark)

Notes and references

| [1] |

We used transparent "BVDA Environmental Gel Lifters", Art.no. B-17000, from:

P-B Miljø

Enebaervej 7

DK-8850 Bjerringbro

however, many similar products exist. Sampling of dust is carried out by placing a strip of the dust lifter gel directly on the dusty surface, then applying a slight pressure with a roll (see right). The dust sample adhere to the gel surface, which can be covered with a protective polyester foil for transport back to the lab. The gel can either go directly under a microscope, or if necessary be sandwiched between two glass slides.

|  |

| [2] |

ImageJ software: http://rsb.info.nih.gov/ij/

|

| [3] |

Yoon, Brimblecombe (2000): "Soiling by coarse particles in the museum environment". Third Indoor Air Quality Meeting, Oxford Brookes University 10th-12th July 2000, http://iaq.dk/iap/iaq2000/2000_15.htm

Yoon, Brimblecombe (2000): "Clothing as a source of fibres within museums". Journal of Cultural Heritage, 1, pp. 445-454

Yoon, Brimblecombe (2001): "The Distribution of Soiling by Coarse Particulate Matter in the Museum

Environment". Indoor Air, 11, pp. 232-240

|

The Viking Ship Museum in Roskilde: http://www.vikingeskibsmuseet.dk/

Large files (ca. 1.2 MB) may take some time to load

Author to whom correspondence may be addressed:

Morten Ryhl-Svendsen

National Museum of Denmark

Department of Conservation, The Laboratory

Brede

P.O. Box 260

DK-2800 Kgs. Lyngby

Denmark

E-mail: morten.ryhl-svendsen@natmus.dk

|